HPLA - High-Power Laser Attenuator

Superior quality laser attenuator using Glan-Taylor polarizers.

Variable attenuators are frequently configured using a combination of a half wave retardation plate and a linear polarizer. Light is input through the retardation plate, the rotation of which produces a rotation in the angle of the plane of polarization as seen entering the polarizer. By Malus' law, the relative transmission of this combination (ignoring other loss mechanisms) is given by the square of the cosine of the relative angle between the plane of the input polarization state and that of the transmission state of the polarizer. This approach relies on the input light being in a well defined linear polarized state and the maximum attenuation will be dictated by the purity of the input polarization state. It is also wavelength dependent by definition as it relies on the retardation plate providing a half wave retardation which of course it will do only for certain wavelengths

This alternative design of optical attenuator uses a pair of high quality Glan-Taylor polarizers and therefore can be used at a choice of wavelengths between 0.35-2.0µm (subject to variations in transmission of the AR coatings). Maximum continuous rating is 200W/cm2 and peak power handling is up to 500MW/cm2 for q-switched pulses (1064nm). If the attenuator is used with plane polarised light the maximum transmission is ~90% and with unpolarised light the maximum transmission is ~45% (lower if un-coated prisms are used for maximum transmission uniformity).

The input polariser is rotated through up to 90° and energy in the side exit beam is dumped onto a light absorbing block. If required the block can be removed and the side exit beam allowed to leave the attenuator. The output polarization state remains fixed for any degree of attenuation as only the input polarizer rotates.

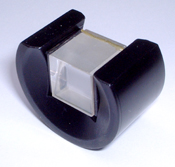

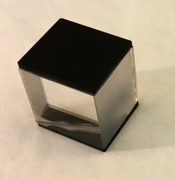

The design of this device has been updated to make it more compact than the original design and also to make it compatible with the popular 30mm cage systems, available from several manufacturers. This also allows for a greater precision in the readout of the rotation angle at which the variable Glan-Taylor polarizer is set. Another benefit of this change is that we can now offer a version with a precision, micrometer driven adjustment of the rotation (in addition to the quick adjustment) that allows for much finer control over the rotation setting, required for obtaining the maximum possible extinction setting. This version is shown below whilst the basic version is shown at the top of the page.

Specifications

| Dimensions (see Interface Diagrams) | |

| Mounting | M4 threaded hole / 30mm Cage System |

| Apertures Available | 10, 12 or 15mm |

| Maximum Continuous Rating | 200W/cm2 * |

| Maximum Peak Power | 500MW/cm2 * |

| Operating Range | 0.35 - 2.0µm * |

| Attenuation Range | 0.4 - 60dB |

| Beam Deviation | <3 minutes of arc |

| Wavefront Distortion | <1/4 |

| Input Polarisation State | Any |

| Output Polarisation | Plane Polarised |

* New for 2013

The HPLA models are now available using alpha-BBO Glan-Taylor polarizers for UV and even higher power applications - please enquire.

Other Options

As you should have guessed by now, you should not be limited by what you see on the page when you come to Leysop. We specialize in providing optimum solutions for your application rather than just those which are convenient for us. The first thing to consider is the choice of polarizer. There may be times when our standard solution with conventional Glan-Taylor polarizers does not fit your exact requirements, for example, if you need to use the rejected side exit beam (so the device is more of a variable beam-splitter) then you may be better to use a version in which the input polarizer is indeed replaced with a halfwave plate and the output polarizer is of the beam-combining type (the angled side exit of this version improves wavefront quality considerably). Another requirement might be for higher field of view, in which case a Glan-Thompson type polarizer is a better choice although the cemented design will limit the optical power handling. Another option which would work best with small diameter beams is to use a beam displacement rhomb, we can engineer a suitable beam-stop or pick-off as required.

The other area where significant enhancements may be made to the design is in automation. It is a relatively straightforward option for us to provide the optical components mounted in a motorised rotation stage which with a suitable controller may be used to give repeatable, hands-off control of attenuation. Please enquire about any options you would like to see.