BBO Pockels cells

BBO Pockels cells for High Repetition Rate Q-switching & Pulse-Picking at High Powers

Background

Technically we should be discussing β-BBO to distinguish it from the α-BBO form which although chemically identical has a centre of symmetry in its crystal structure which robs it of any electro-optic effect (but it still makes an excellent polarizer)! For brevity though we shall just refer to BBO from now.There are of course quite a few materials which do possess an electro-optic effect and selecting the optimum material for a given application is not always easy. It will depend on many factors, but when high power handling is important it is usually the case that BBO provides by far the best solution. It features good optical transparency from around 200nm to over 2µm and very importantly for intra-cavity laser operation, offers a high resistance to optical damage with power handling >3GW/cm2 for 1ns pulses at 1064nm. Average power handling is also far higher than in other materials and it is possible to use BBO Pockels cells at average power levels of hundreds of watts and power densities of several kW/cm2

In addition to this excellent power handling, BBO Q-switches have very low levels of piezo-electric resonances. For Q-switching, lasers up to 50 or even up to 100kHz are practical, for pulse picking applications for which the electrical excitation pulse is very much shorter the limit has been demonstrated to be >5MHz (driver limited)

Comparisons with RTP are fairly obvious as they both lend themselves well to high repetition rate applications. The advantage of BBO is that the optical propagation is along the optical axis of the material (Z-direction) so there is no static birefringence and thermal stability is excellent. This, along with the high crystal homogeneity, provides a high extinction ratio which for single crystal devices is usually ~1,000:1 or even higher. In RTP the light propagation axis is either along the X or Y axes, both of which exhibit birefringence so some form of birefringence compensation is required. It is more difficult to achieve such high contrast therefore in the RTP Pockels cell.

Surely then there has to be a reason why BBO is not the preferred EO material for almost all applications? There is, and that is the operating voltage. The electro-optic coefficient of BBO is quite low and so for a given crystal dimension the half wave voltage will be much higher than for just about any comparable Pockels cell. For example, a 3x3mm cross section by 20mm long crystal has an effective half wave voltage at 1064nm of approximately 7kV around 5 times higher than an RTP Pockels cell of similar crystal dimensions. Even though it is a transverse field device so can be made more sensitive by making crystals long and thin, there are practical limits to the lengths of individual crystals which are related to the aperture. For up to 5x5mm cross section crystals, the maximum practical length in the Z-direction is 25mm.For crystals greater than 5mm aperture but up to 12mm, the maximum available length is 20mm and for larger apertures the length must fall even more. It is often the case then that the only practical method of bringing voltages down to acceptable levels (particularly with larger aperture crystals) is to use two crystals in series. This is not like the RTP cell, there is no birefringence compensation occurring, but it is just to apply the available voltage to two crystals in series and hence to double the effect produced.

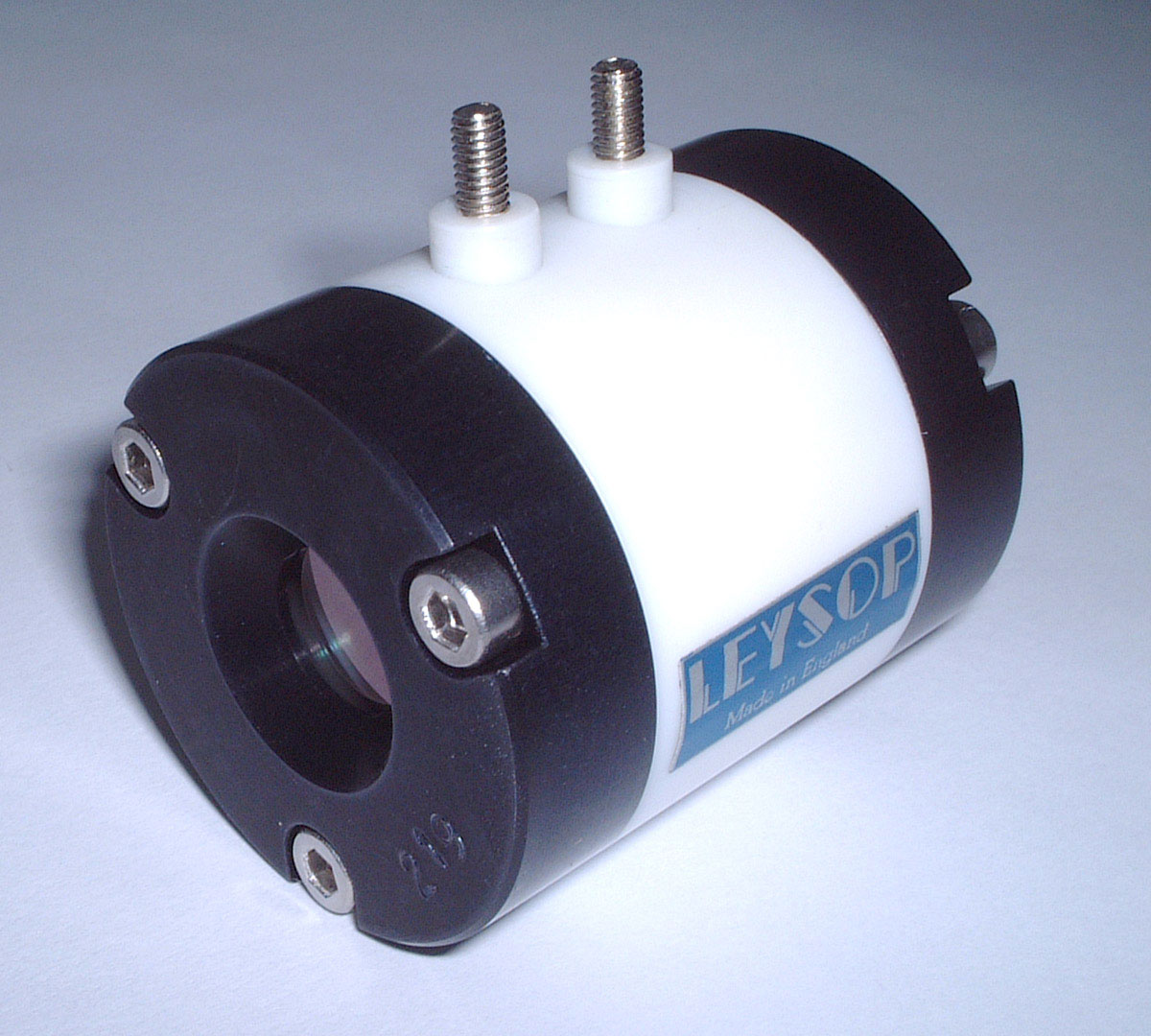

Although we will make just about any practical BBO Pockels cell to suit your requirements, there are a number of standard sizes and combinations of crystals which we try to use. Usually the devices are mounted in a 35mm diameter package, the length of which is determined by the total length of BBO crystal(s) used. The exception to this is where a package with coaxial connectors is required, either for safety (use on an open bench) or for reasons of the drive scheme (e.g. a through connected driver) or in the case of water-cooled devices (see below). Whichever package style is used, it must usually be sealed with optical windows because BBO is mildly hygroscopic and cannot withstand operation in high levels of humidity without degradation over time of the optical faces. If the environment is carefully controlled and low humidity, BBO Pockels cells may be successfully operated in windowless packages.

The standard devices are designated as with most of our transverse field Pockels cells, by a part number which defines the material, the aperture, the crystal length, and any AR coating specifications. A 4mm aperture crystal of length 25mm with AR coatings for 1064nm then would be model BBO-4-25-AR1064. A model with crystal length number greater than 20 or 25mm (depending on aperture) will be a double crystal cell, e.g. BBO-6-40-AR800.

General/Typical Specifications

| Parameter | Value |

| Transmission (e.g. at 1064nm) | >98.5% |

| Apertures Available | 2, 3, 4, 5, 6, 7, 8mm standard * |

| Half wave voltages at 1064nm | Approx. 7kV for 3x3x20mm crystal ** |

| Contrast ratio | >30dB typically |

| Capacitance | From 5 to 10pF typically |

| Damage Threshold | >1GW/cm2 at 1064nm (t = 10ns) |

| Available Wavelengths: | 220nm - 2,000nm *** |

* Larger apertures up to 12mm are available but practical limitations of operating voltage provide some restrictions, for example, double crystal cells may be required even for quarter wave operation.

** For other crystal dimensions the voltage will scale linearly with aperture and inversely with length.

*** Longer wavelengths may impose restrictions on aperture because of voltage limitations.

Water-Cooled Versions

This is an exciting option which really lifts the operation of BBO Pockels cells to a higher level. There are two reasons for using water-cooled BBO Pockels cells, higher repetition rates and higher optical power handling. Firstly, dielectric heating losses in BBO are generally higher than in say RTP and because of the higher voltages employed there is a lot of electrical energy dumped into a BBO Pockels cell. For frequencies around 1MHz and higher, we have found that by employing a special package design with enhanced thermal management, we are able to retain the contrast performance seen at lower frequencies. A modest amount of water-cooling can enhance this further as frequencies are increased above 1MHz.

The other main reason for employing water cooling of course is to allow handling of higher optical powers. Standard devices are usually fine for powers to 100W or even somewhat more (it does depend a little on application of course). For higher powers it is definitely an advantage to water-cool the crystal(s) and we have a number of single, double and even triple crystal designs available from 3mm to 8mm aperture and larger is of course possible.

The water-cooled housings provide almost symmetrical heat dissipation from the crystal(s) and also provide cooled apertures.

Applications

The main areas of application for BBO Pockels cells are the same as for RTP, for moderate apertures where a high repetition rate is required and KD*P Pockels cells would suffer from piezo-electric resonances. A typical example would be pulse picking where a high repetition source, typically a ps or fs mode-locked laser, is reduced from the typical MHz rates down to a much lower rate. The advantage of BBO is in handling substantially higher optical power levels than RTP (or indeed any other) Pockels cell can withstand. This is true in any application including Q-switching where our water-cooled cells have been operated at >500W output power. Regenerative amplifiers are also a primary application for BBO Pockels cells, providing low loss, high power handling and freedom from the temporal problems that can affect KD*P cells used with long electrical pulses. For these and other applications we can recommend drivers from BME KG of Germany who have unrivalled expertise in high rate Pockels cell drivers and with whom we have demonstrated 20MHz continuous rate pulse picking systems.

We can also provide BBO Pockels cells in a format which is well suited to use with fast, 50Ω impedance pulse drivers for sub-ns rise time applications. This makes them suitable for pulse slicing of high power and especially UV light sources.